Packaging Vents

Application: Industrial Chemicals; Agrochemicals; Household Chemical Products

Packaging is the general name for containers, materials, and auxiliaries made to protect products, facilitate storage and transportation, and promote sales in the process of product circulation. As a relatively new industry, packaging is widely used across industries and include a variety of container categories from traditional cartons and paper bags to plastic containers with various volumes. In return, the diversity of products promotes the application of packaging in the chemical industry.

Some chemicals are flammable, combustible, toxic, and corrosive. Such dangerous characteristics may lead to accidents if handled improperly in transportation and may affect production, cause economic losses, or even bring casualties to people or pollutions to the environment. As chemicals are used more widely, accidents are also becoming more frequent due to improper packaging, transportation, and storage, leading to a greater impact on people and the environment.

Therefore, strict requirements are put on the chemical industry around the globe on procedures like processing, production, packaging, and transportation. In addition, the inherent characteristics of chemicals have made the control and preservation extremely difficult, resulting in increased costs and reduced profits and bringing severe challenges for both upstream and downstream enterprises. In order to accommodate to the above challenges, enterprises in the chemical packaging industry must always introduce new technologies to deal with various packaging problems.

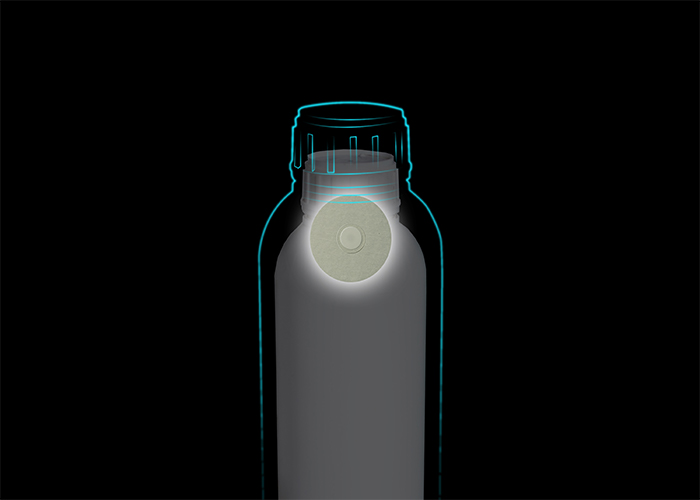

Venting is a common and urgent issue. As departments and enterprises pay more attention to chemical packaging and continuously introduce new materials for better packaging quality, “Clarketech” such as venting products began to be used on packaging bottles (caps). This kind of venting product can be applied not only on traditional packaging boxes and bags, but also on other packaging containers such as hollow plastic containers with volume sizes of 50ml-5L, 5L-200L, and other specifications, such as IBC.

As a global venting solutions supplier, IPRO provide various products to meet the application needs of clients, prevent chemicals from being polluted during processing and production, improve product performance, increase product value, and eventually improve profit margin.

Features of IPRO venting products for packaging:

1. It maintains good airflow to balance the pressure differences inside and outside the container, and avoid bottle expansion or contraction.

2. It has good surfactant resistance and can ensure good airflow even when in contact with high viscosity liquids.

3. It can prevent liquids from leaking, improving product safety, and protecting the users and the environment.

Chemical packaging mainly includes industrial chemicals, agricultural chemicals (pesticides and fertilizers), and household chemicals (detergents). These chemicals are corrosive and volatile, with possible chemical reactions caused by changes of the external environment (temperature and altitude). Inappropriate venting packaging will cause leakage or container deformation, reduce consumer satisfaction, and affect brand reputation.

+86-571-89923680

+86-571-89923680 sales@ipromembrane.com

sales@ipromembrane.com 13F, Building 1, Zicheng International Innovation Center, No.39 Jincheng Road, Xiaoshan District, Hangzhou 311215, China

13F, Building 1, Zicheng International Innovation Center, No.39 Jincheng Road, Xiaoshan District, Hangzhou 311215, China Linkedin

Linkedin Facebook

Facebook Twitter

Twitter Youtube

Youtube