2022-07-08

Release Time:2022-06-20

Share:

In 1954, DuPont company invented a non-stick pot that quickly won the hearts of American housewives and became popular around the world. It wasn’t until 2015, almost 60 years later, that the additive used in non-stick pot production was banned by the United States. The long-term use of this additive, PFOA, has led to the presence of PFOA in most people around the world.

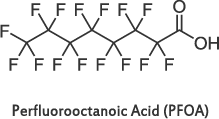

What is PFOA?

PFOA and its salt substances are a type of synthetic liver carcinogen with moderate toxicity, that cannot be decomposed in the natural world. In the early days of PTFE production, PFOA was used in a variety of civil products. In 2018, a documentary named The Devil We Know introduced the serious consequences of PFOA pollution: neonatal deformities, massive livestock deaths, and an increase in cancer incidence rate.

Fortunately, it was not too late. The amount of PFOA present in nature is not enough to affect the lives of ordinary people. On May 23, 2001, 92 countries and regional economic integration organizations, including the Chinese government, signed the Stockholm Convention (POPs). In 2020, POPs included PFOA as a control target.

As a domestic leading enterprise in R&D and production of ePTFE membranes, IPRO has long been committed to the research of these basic materials. With comprehensive capabilities in raw material R&D, processing, and production, finished product testing and application technology, besides providing industry-leading solutions, it also ensures product compliance.

In a single automotive vehicle, hundreds of parts require breathable membranes. After POPs included PFOA, most manufacturers in the membrane industry failed to meet the new regulations. Membrane suppliers were reluctant to invest in basic material R&D as it did not generate commercial benefits in the short term. After the introduction of the new regulations, products of several manufacturers were tested in Auto OEMs and reported as PFOA levels that exceeded the regulations. Many world-renowned automotive electronic part enterprises are looking for suppliers who can provide PFOA free breathable membrane products.

All of IPRO’s products meet the requirements of the new POPs regulations. Not only can third-party test reports be provided, but we can also conduct index tests on PFOA in its self-owned laboratories.

At the present time, IPRO supplies PFOA-free breathable membranes to many auto-part companies throughout the United States and Germany. Many domestic automotive electronics manufacturers are conducting research in this field, but because China’s requirements on PFOA are not as strict as those of the EU, many manufacturers still follow the current standard and use ePTFE membrane with high PFOA ratios. IPRO is lobbying for relevant manufacturers to switch to PFOA-free products. At the same time, IPRO will continue to invest in basic materials research, develop new materials and technologies, and make its own contribution to the sustainable development of human society.